Published Date: Aug 22 2023

In the realm of biotechnology, where innovation knows no bounds, recombinant trypsin production stands as a prime example of how genetic engineering can revolutionize enzyme manufacturing. This remarkable process not only addresses the limitations of traditional trypsin extraction but also unlocks a multitude of advantages that have far-reaching implications. In this blog, we'll delve into the intricacies of recombinant trypsin production, exploring its significance, methods, and potential applications.

Understanding Recombinant Trypsin Production

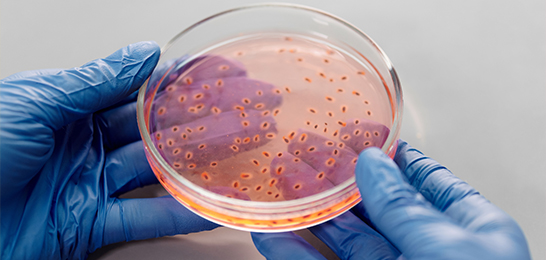

At its core, recombinant trypsin production involves harnessing the power of genetic manipulation to create a sustainable and controlled source of this crucial enzyme. The process begins with the isolation of the trypsin gene, which is then inserted into a host organism, commonly bacteria or yeast. Through this genetic engineering, the host organisms are transformed into miniature trypsin factories, producing the enzyme in abundance.

Methods of Recombinant Trypsin Production

The choice of host organism plays a pivotal role in recombinant trypsin production. Bacteria and yeast are popular options due to their well-established genetic manipulation techniques and rapid growth rates. These systems offer the advantage of scalability and yield optimization, making them ideal candidates for large-scale production. Once the host organisms are engineered, they are cultivated in bioreactors through fermentation. This step involves optimizing growth conditions, nutrient supply, and oxygen levels to achieve maximum enzyme production. After fermentation, downstream processing techniques such as cell harvesting, cell disruption, and purification are employed to isolate and purify the recombinant trypsin.

Advantages of Recombinant Trypsin Production

One of the most significant advantages of recombinant trypsin production is the consistency and purity it offers. Traditional trypsin extraction from animal sources often resulted in variable enzyme quality due to inherent differences between animals. Recombinant production ensures uniform enzyme characteristics, eliminating batch-to-batch variability. The scalability of recombinant production methods is a game-changer. Enzyme manufacturers can meet increasing demands without relying on a limited supply of animal sources. Moreover, the controlled fermentation processes enable fine-tuning of production conditions, leading to improved yields and more efficient enzyme manufacturing. Recombinant trypsin production aligns with ethical and sustainable practices by reducing the need for animal-derived enzymes. This not only supports animal welfare but also contributes to environmentally friendly manufacturing processes, making it a conscientious choice for companies and industries.

Potential Applications

Recombinant trypsin has transformed the fields of bioprocessing and cell culture. Its consistent quality and controlled activity levels optimize protein production, leading to higher yields and improved efficiency. In cell culture, the enzyme's gentleness during cell detachment preserves cell viability, fostering advancements in regenerative medicine, drug discovery, and tissue engineering. The reliability of recombinant trypsin makes it an invaluable tool in research and diagnostics. Scientists can conduct experiments with confidence, knowing that the enzyme's consistent quality will yield reproducible results. This is particularly crucial in fields like proteomics and genomics, where accuracy is paramount.

Recombinant trypsin production is a testament to the incredible potential of genetic engineering in biotechnology. Its advantages in terms of consistency, scalability, and ethical considerations are propelling enzyme manufacturing into a new era. As technology advances, we can anticipate further refinements in production methods, ultimately leading to more cost-effective, sustainable, and efficient enzyme production. Whether in the laboratory, the bioprocessing facility, or the clinic, the impact of recombinant trypsin production is paving the way for a brighter future in biotechnology.