Published Date: Apr 09 2025

Zhuhai Gene-Biocon Biological Technology Co., Ltd. offers Semaglutide Intermediate P29, a critical building block for synthesizing Semaglutide—a leading GLP-1 analog used in diabetes management. Engineered for excellence, our 29-peptide intermediate combines cutting-edge biotechnology with rigorous quality control to empower pharmaceutical R&D and production.

Core Advantages of Semaglutide Intermediate P29

1. Animal-Free, Risk-Free Production

Zero Animal-Derived Components: Eliminates risks of viral contamination, prion transmission, or foreign pathogens.

Safe for Regulatory Compliance: Ideal for markets with strict guidelines on animal-origin materials (e.g., EU, US).

2. High Purity & Stability

Purity ≥90% (HPLC): Ensures consistent performance in downstream synthesis.

Long-Term Stability: Stable for 24 months at ≤-15°C, supported by cold-chain logistics.

Optimized Solubility: Easily dissolves in purified water (pH 11.0–11.5) for seamless integration into synthesis workflows.

3. Scalable GMP Manufacturing

GMP-Standard Production: Full compliance with global pharmaceutical standards.

Commercial-Grade Supply: Available in bulk quantities with flexible packaging (R&D to industrial scale).

Custom Solutions: Tailored purity, formulation, or documentation support upon request.

Technical Excellence

Items | Characteristics |

Source | E.Coli |

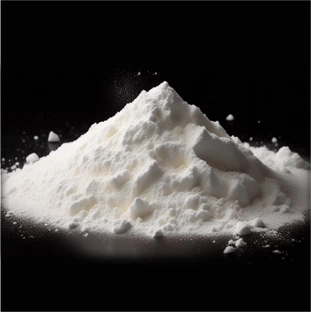

Appearances | White or off-white freeze-dried powder |

Solubility | Soluble in water (pH11.0-pH11.5) |

Purity(HPLC) | ≥90.0% |

Loss on Drying | ≤10.0% |

Content | Calculated on a dry basis, the content of Semaglutide intermediate P29 should be ≥ 90.0% |

Application & Workflow Integration

Semaglutide Intermediate P29 serves as the backbone for synthesizing Semaglutide’s active pharmaceutical ingredient (API). Key steps include:

Dissolution: Reconstitute at 5–10 mg/ml in purified water (pH 11.0–11.5).

Structural Modification:

Attach an 18-carbon fatty diacid side chain to lysine at position 26.

Link a dipeptide to glutamic acid at position 9.

Purification: High-yield downstream processing to achieve final API quality.

Why Choose Gene-Biocon?

End-to-End Expertise: From gene engineering to commercial-scale fermentation and purification.

Documentation Support: Comprehensive COA, CERTIFICATE OF ORIGIN, Statement of Animal-free and regulatory guidance.

Reliable Supply Chain: Ice-pack shipping with guaranteed stability during transit.

Compliance & Safety

For Research/Production Use Only: Not intended for human or clinical applications.

Handling Guidance: Avoid strong acids, oxidizers, or solvents to prevent protein denaturation.

Partner with Confidence

Elevate your Semaglutide production with a trusted, future-ready intermediate.

Contact Us Today:

+86-756-6348118 | inquiry@g-biotec.com