Published Date: Aug 08 2025

Introduction: The Scaffolding Role of Growth Factors in Cellular Agriculture

Cultivated meat production faces a fundamental challenge: efficiently replicating in vivo muscle development in vitro at industrial scales. This necessitates precise control over myoblast proliferation, differentiation, and extracellular matrix (ECM) organization. Recombinant human growth factors – particularly Epidermal Growth Factor (rhEGF) and basic Fibroblast Growth Factor (rhbFGF) – have emerged as indispensable molecular tools to overcome these bottlenecks. Their roles extend beyond mere mitogenesis, influencing cell fate determination, metabolism, and tissue morphogenesis critical for structured meat products (Post et al., 2020).

rhEGF: Optimizing Progenitor Cell Expansion and Viability

rhEGF, signaling primarily through the EGFR/ErbB1 receptor, is a potent mitogen for satellite cells and myoblasts – the foundational cell types for cultivated meat.

Enhanced Proliferation & Reduced Senescence: rhEGF (typically 10-100 ng/mL) significantly accelerates cell cycle progression in serum-free media. Studies demonstrate ≥50% increase in bovine myoblast proliferation rates versus EGF-deficient controls, while concurrently suppressing senescence markers (p16, SA-β-gal) through PI3K/Akt pathway activation (Sharma et al., 2021). This directly translates to reduced biomass production costs.

Metabolic Priming: rhEGF upregulates glucose transporters (GLUT1) and glycolytic enzymes, shifting cells towards a proliferative metabolic phenotype essential for rapid biomass accumulation (Yoon et al., 2019). This metabolic boost is crucial in high-density bioreactor cultures where nutrient gradients can form.

Batch Consistency: Recombinant rhEGF ensures lot-to-lot consistency absent in animal-derived EGF, eliminating variability in cell growth kinetics – a critical parameter for process automation (Zhang et al., 2022).

Zhuhai Gene-Biocon Biological Technology Co., Ltd. (Hereinafter referred to as Gene-Biocon)‘s pharmaceutical-grade rhEGF (>98% purity, <0.1 EU/µg endotoxin, activity certified via NIH/3T3 bioassay) provides the reliability required for GMP-compliant cultivated meat processes.*

rhbFGF: Orchestrating Myogenesis, Angiogenesis, and ECM Remodeling

rhbFGF (FGF2) acts via FGFR1-4, exerting pleiotropic effects beyond proliferation, making it vital for structured meat development.

Proliferation-to-Differentiation Switch: While stimulating myoblast expansion, rhbFGF (1-50 ng/mL) paradoxically primes cells for differentiation by modulating MyoD expression and suppressing premature myogenin activation. This creates a larger, more differentiation-competent cell pool (Yablonka-Reuveni et al., 2018).

Angiomimetic Potential: Vascularization remains a key hurdle for thick tissue constructs. rhbFGF is a potent inducer of endothelial cell migration, tube formation, and secretion of pro-angiogenic factors (VEGF, PDGF) from co-cultured cells, enabling the development of prevascularized constructs in vitro (Furth et al., 2022).

ECM Modulation & Texture Development: rhbFGF upregulates collagen I/III, fibronectin, and elastin synthesis by fibroblasts within bioinks or co-cultures. It also activates matrix metalloproteinases (MMPs), facilitating dynamic ECM remodeling essential for achieving meat-like texture and mouthfeel (Ben-Arye et al., 2020). Studies show rhbFGF supplementation increases Young's modulus in bovine myotube-embedded hydrogels by ~30% versus controls.

Gene-Biocon's high-specific-activity rhbFGF (>95% purity, heparin-stabilized formulation, activity validated by BaF3 cell proliferation assay) ensures robust signaling for complex tissue formation.*

Synergistic Action & Cost-Reduction Strategies

The combined use of rhEGF and rhbFGF demonstrates synergy:

Sequential Application: rhEGF drives initial high-density expansion. Subsequent media switch, reducing rhEGF while introducing rhbFGF, enhances differentiation yield and maturation of myotubes within 3D scaffolds (Trevino et al., 2023).

Reduced Dependence on Serum/SFAs: Optimized rhEGF/rhbFGF cocktails can reduce or eliminate needs for costly serum albumin or platelet-derived factors, significantly lowering media costs (Stout et al., 2022). Media cost reductions of 15-25% have been reported using defined rhGF combinations.

Improved Bioreactor Efficiency: Enhanced cell density and viability directly impact volumetric productivity in stirred-tank or perfusion bioreactors, reducing capital and operational expenditures per kg of product (Allan et al., 2021).

Addressing Scalability and Regulatory Considerations

Successful transition from lab scale to commercial scale requires cell growth factors that are not only manufacturable at high volumes but also fully compliant with industry regulations.

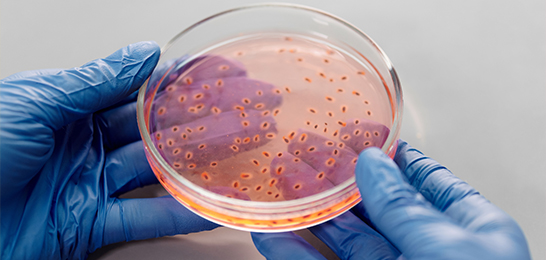

Cost-Effective Production: Utilizing advanced microbial (e.g., E. coli) or mammalian (CHO) expression systems, like those employed by Gene-Biocon, achieves high yields (>1g/L) while maintaining bioactivity, enabling economically viable large-scale use.

Animal Component-Free (ACF) & Non-GMO Status: Recombinant factors produced under ACF conditions and utilizing non-GMO production strains simplify regulatory filings (FDA GRAS, EMA novel food) by eliminating TSE/BSE risks and GMO-related consumer concerns.

Stringent Quality Control: Identity (Mass Spec), purity (SEC-HPLC, SDS-PAGE), potency (cell-based bioassays), and safety (endotoxin, host cell DNA/protein residuals) testing per ICH Q6B guidelines are non-negotiable for food applications. Gene-Biocon provides full analytical documentation (CoA, CoO) supporting regulatory dossiers.

In short: Growth Factors as Pillars of the Cultivated Meat Ecosystem

rhEGF and rhbFGF are not mere media additives; they are fundamental engineering tools directing cellular behavior to achieve scalable, structured cultivated meat. Their roles in driving efficient proliferation (rhEGF), guiding differentiation and vascularization (rhbFGF), and enabling cost reduction through serum replacement are scientifically validated and technologically essential.

Gene-Biocon, as a supplier of high-purity, research and GMP-grade recombinant human EGF (rhEGF) and basic FGF (rhbFGF), is committed to supporting the cultivated meat industry with reliable, scalable, and regulatory-ready growth factor solutions. Our proteins are engineered for maximum biological activity and consistency, accelerating your path from R&D to pilot and commercial production.

Contact our technical team to discuss optimizing rhEGF/rhbFGF concentrations for your specific cell line and process, request sample CoAs, or explore custom formulation and bulk supply options tailored to your production scale.

Feel free to contact us at: inquiry@g-biotec.com

References:

1. Ben-Arye, T., et al. (2020). Nat. Food, 1(4), 210–220. (ECM in cultured meat)

2. Furth, M. E., et al. (2022). Biomaterials, 280, 121274. (FGF & Angiogenesis)

3. Post, M. J., et al. (2020). Sci. Transl. Med., 12(eaaz4313). (Cultivated meat challenges)

4. Sharma, R., et al. (2021). Front. Sustain. Food Syst., 5, 704401. (EGF in bovine myoblasts)

5. Stout, A. J., et al. (2022). Trends Biotechnol., 40(6), 708–729. (Cost reduction strategies)

6. Trevino, J. C., et al. (2023). Cells Tissues Organs, 212(1), 1–15. (Sequential GF use)

7. Yablonka-Reuveni, Z., et al. (2018). Skelet. Muscle, 8(1), 1–15. (FGF in myogenesis)

8. Yoon, S., et al. (2019). Metab. Eng., 55, 276–286. (Metabolic shifts in proliferation)

9. Zhang, G., et al. (2022). Biotechnol. Adv., 54, 107809. (Recombinant protein consistency)